So, since the petrol engine is running lean and I’d rather make the bike electric than spend time calibrating carburetor, I’ll start the project now – a few months earlier than planned.

This is the victim. A 2012 GasGas ec250f with a 290cc kit installed. I bought it just to do the conversion but had planned on running it as a gas-bike this summer as there are a lot of other projects I have to do… but, well.. I can’t say I’m sad to have to push this project up the priority list. 🙂

I’m going to run a QS180 90h motor paired with an APT96800 controller running at 72v. The reason for chosing 72v instead of 96v is that I’ve got quite a few 72v packs already and got the chargers and BMS:es I need to make this work. There’s nothing preventing me from upgrading to 96v in the future if it turns out it’s too dull at 72v.

I’ve got a pair of 30Ah batteries that are good for around 300A a piece that I’m going to run in this bike for now. Connected in series they should give quite a lot of *umph*, and last – well, hopefully for a bit of fun at least.

The first hurdle in this project is that the QS motor is here at the moment:

Buried under a lot of stuff in the Avant tractor I converted a few years back. The thing is, I need the Avant to keep running for other projects, so I’ll need to kick off replacing the QS with a LightningRods XXL motor I bought a while back for this purpose.

I got a ”special edition” XXL motor with fan cooling that’ll be perfect for the application as it’ll sit stationary under the seat on the Avant. First sub-project will be making the belt wheel fit the axle and keyway of the XXL.

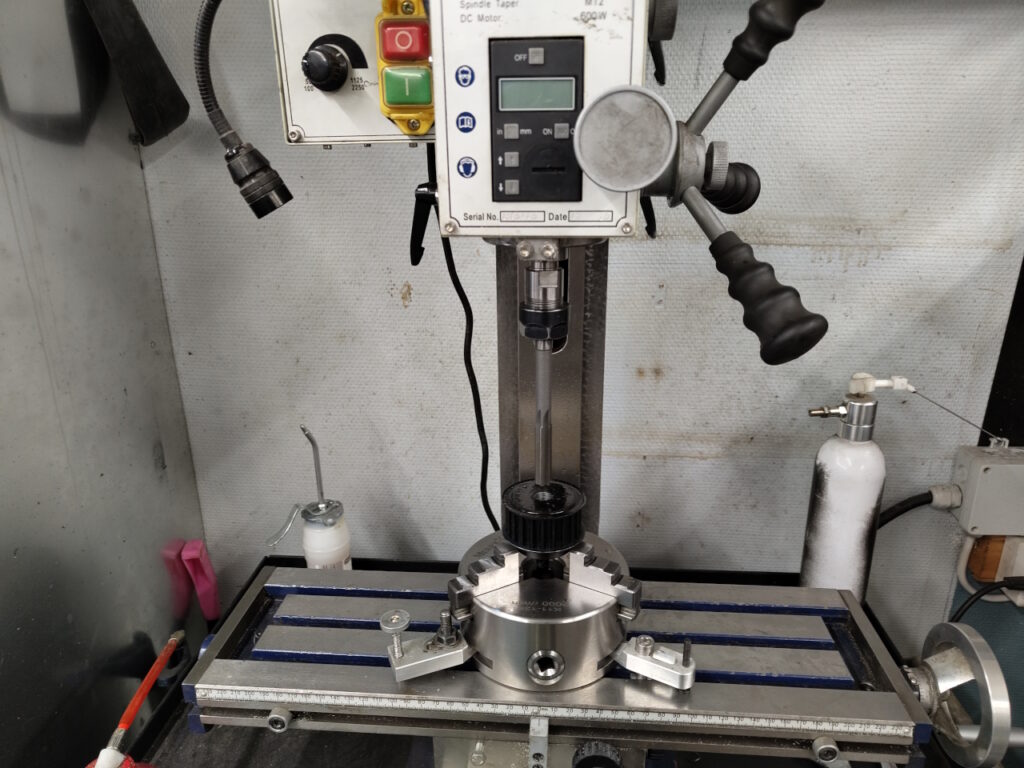

To do this I need the manual mill to be running, and I fried the motor on that one a while back milling unsuitable materials.. In the last post I repaired it with an 800w motor, all that was left to do now was to set it up properly. After a bit of fiddling I got it square enough and set the wheel up in the mill chuck I got just for this purpose, but when doing the first conversion.

Since I don’t have a DRO on the mill (I’ll have to get one later) I’m using a live center to center the part on the mill. I locked down the table to prevent it from moving and bolted down the chuck while keeping it centered with the quill.

Then all I had to do was drill the hole to just under size and ream the hole to size. 12mm hole for 12mm shaft. Perfect!

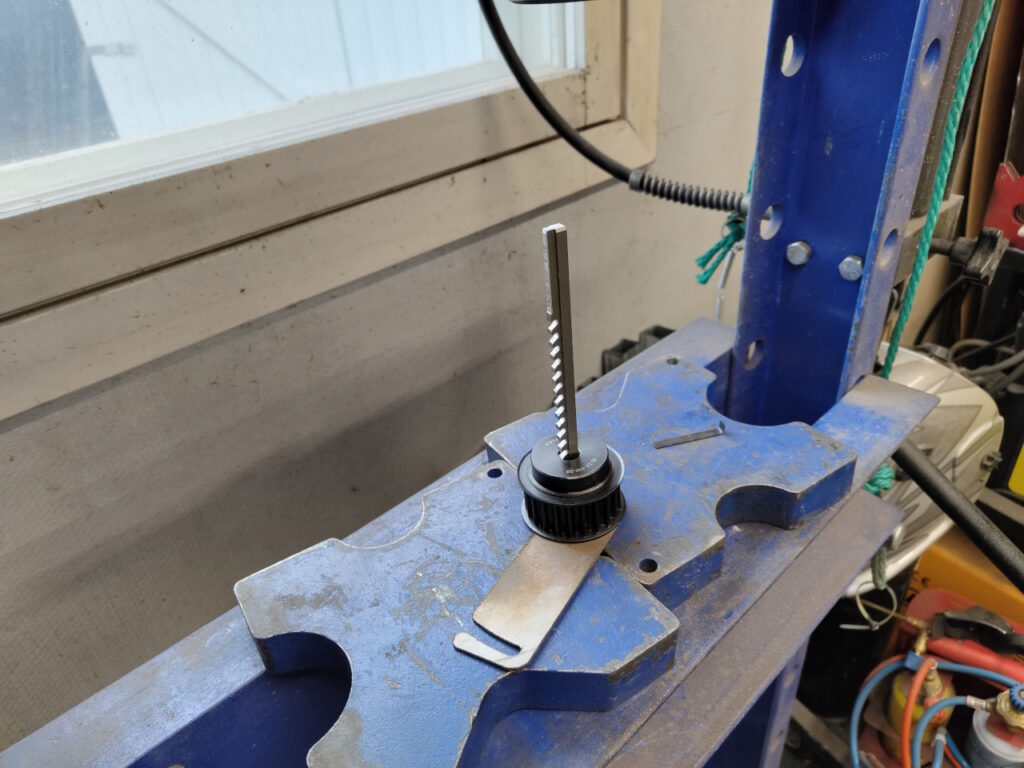

All that was left to do now was the keyway and I’ve got the tools for that.

Unfortunately I didn’t have the sleeve for 12mm holes, and I wanted to make the keyway now… so, sub-subproject: Making the sleeve.

Just had to find a 12mm axle and a tube with 12mm ID. Welded them together and set it up on the mill to make the proper slot.

I don’t know if the reamers are ment for 12mm holes, but there’s not a lot of material left after milling the slot in the sleeve. It’s quite hard to hold on to while taking the last few passes, but it doesn’t have to be perfect.. Good enough is .. good enough.

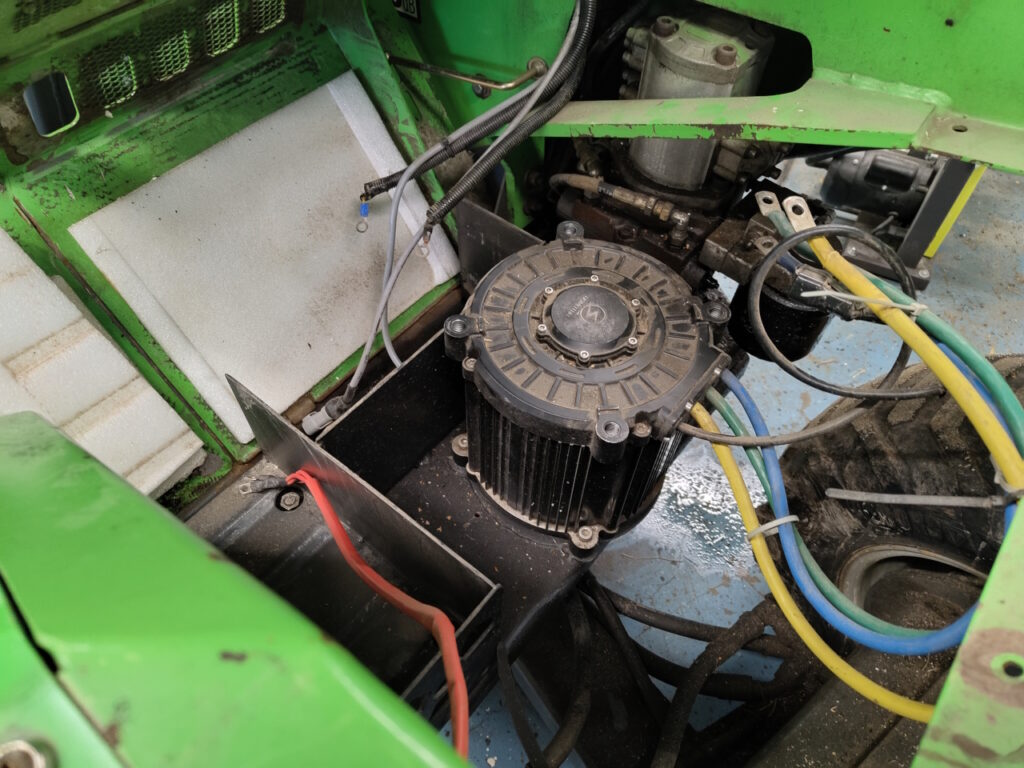

Having made the keyway and made sure the wheel fit on the XXL motor it was time to disect the Avant.

I’ve got to service this machine, it’s been running for years without doing anything to it, and it’s leaking hydraulic fluid from the filter.. That’ll be a later post.

After disconnecting all the wires, removing the battery packs and the controller I could finally get to the motor. Seems I did quite a proper job converting this machine as it’s really servicable. I am however going to try to fit three battery packs instead of the current two when I put it all together to get it running a bit longer. I’ve got two spare packs sitting on a shelf doing nothing constructive at all, better to put one to use.

Having removed the QS motor from the Avant I just had to make a size comparison. 🙂

The smallest one here is the Lightning Rods XL motor. It’s a bit more powerful than the BigBlock I’m using on the runbikes, and those do over 110km/h and are insanely powerful.. super fun toys! The XL is supposed to push about 50% more power than the BigBlock..

The center motor is the XXL that’s going into the Avant. I don’t have the proper numbers for it but it’s a larger diameter motor and quite a lot larger overall. That should give quite a lot more torque and it can push quite a lot of power. The Avant averages about 5kW, so this should be plenty.

To the right is the QS180. It’s a proper beast! I’m super stoked to see what that motor can do on a bike!

After having measured the offset of the belt wheel on the axle I set it up on the mill again to bore the hole larger to fit the retaining clip on the motor axle at the right height.

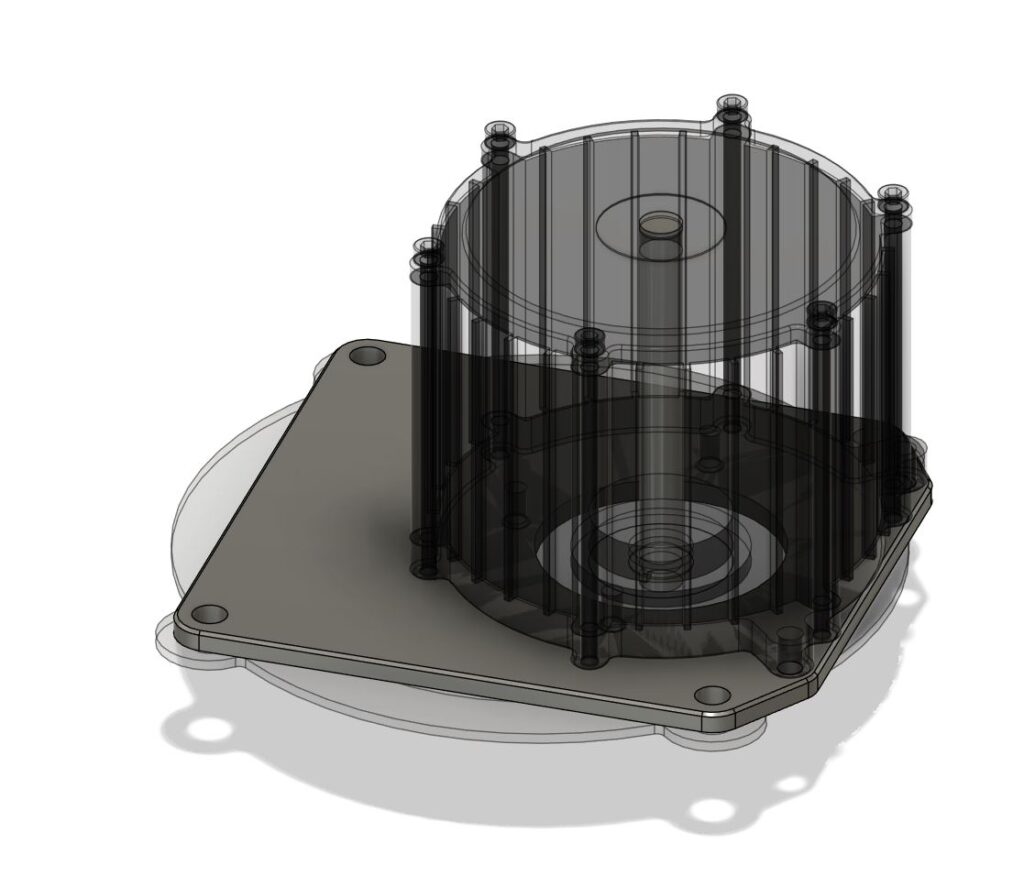

Time for a quick test fit and then CAD to make a conversion plate between the welded QS-motor bolt pattern and the XXL.

The first mockup is on the 3D-printer right now. After test fitting to see how it fits I’ll mill it from aluminium..

To be continued..