So, it’s been a while since I updated the project but it’s been a slow progress.

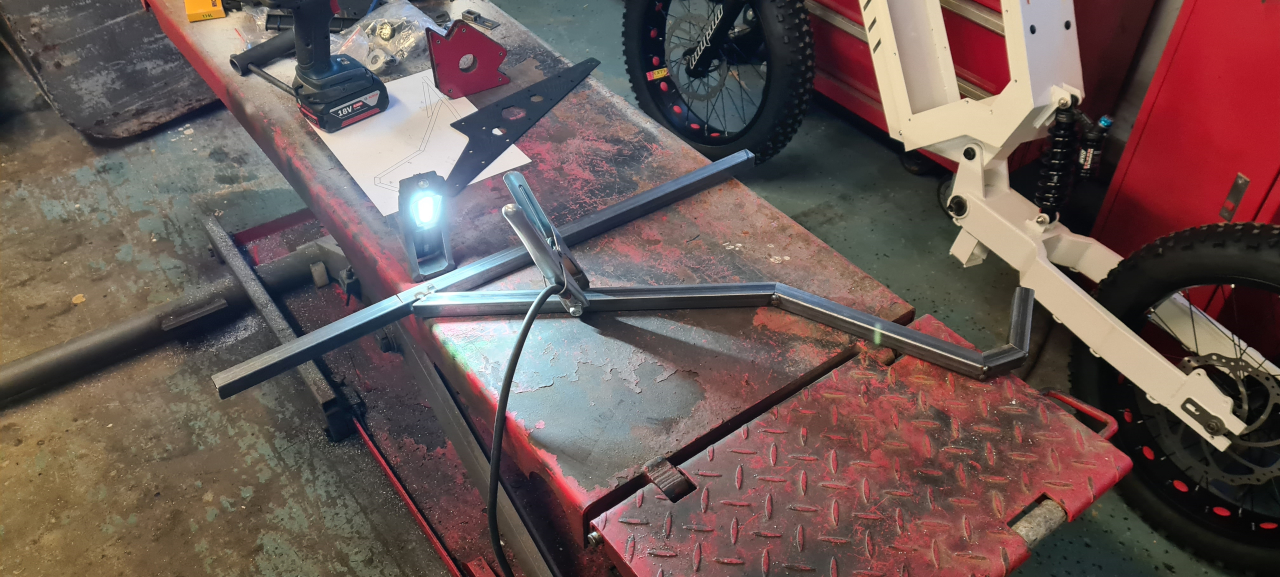

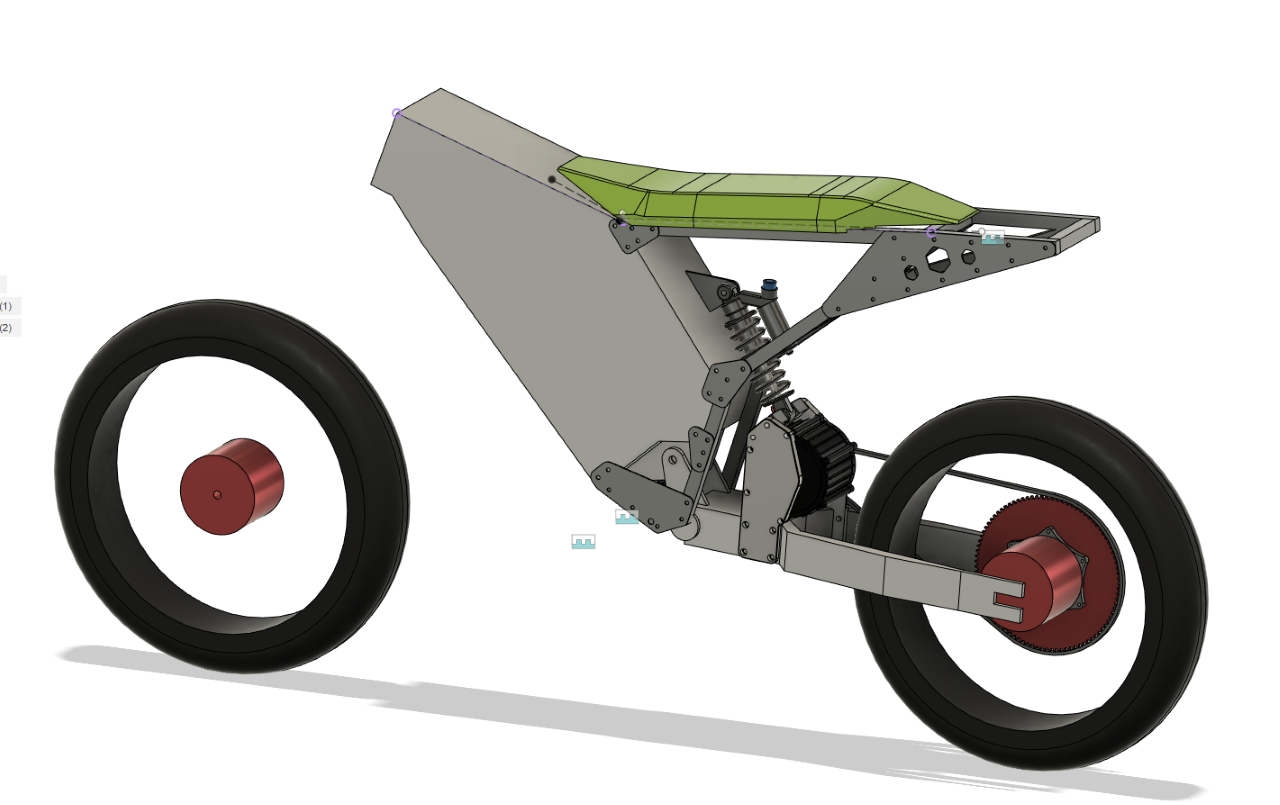

Started by building a mockup for the subframe to test fitment and how it’d look on the frame.

I’m pretty happy with how the mockup looks and fits on the frame, and it seems to be sturdy enough and kind of not too heavy (this isn’t going to be a super light-weight bike anyhow) so, on we go.

After having upgraded the CNC plasma with a better Z-axis it’s good to cut steel sheet with pretty good precision, so I cut the brackets needed for making all the subframe parts from 2mm steel sheet.

The result is pretty awesome for a low-cost DIY contraption..

After a little bit of polishing with the grinder the final result is more than good enough.

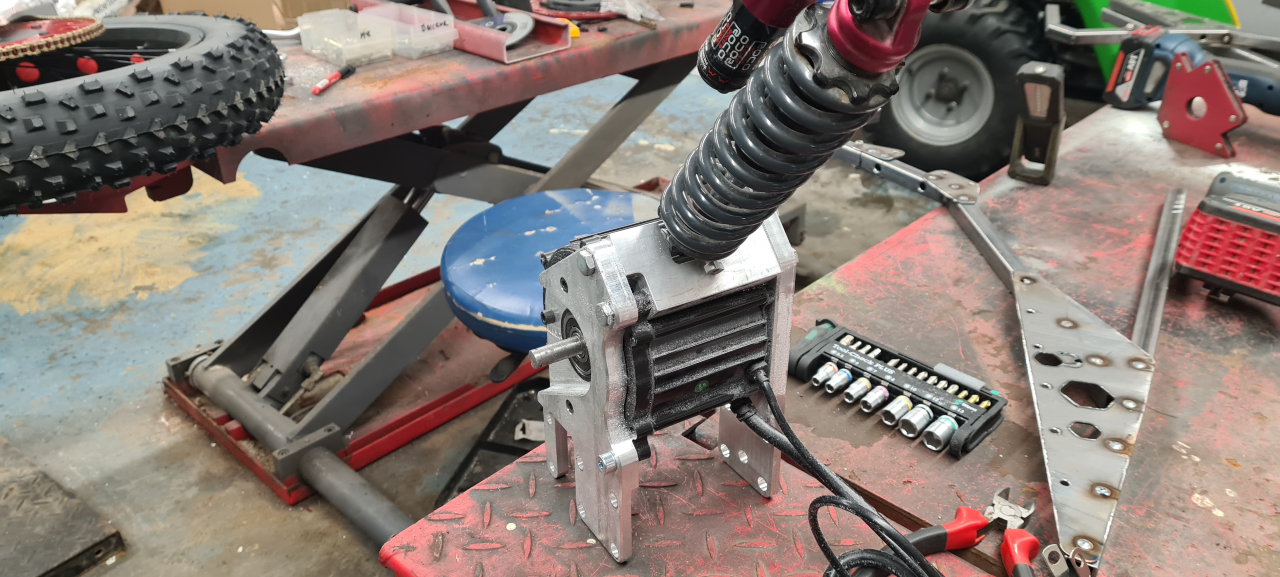

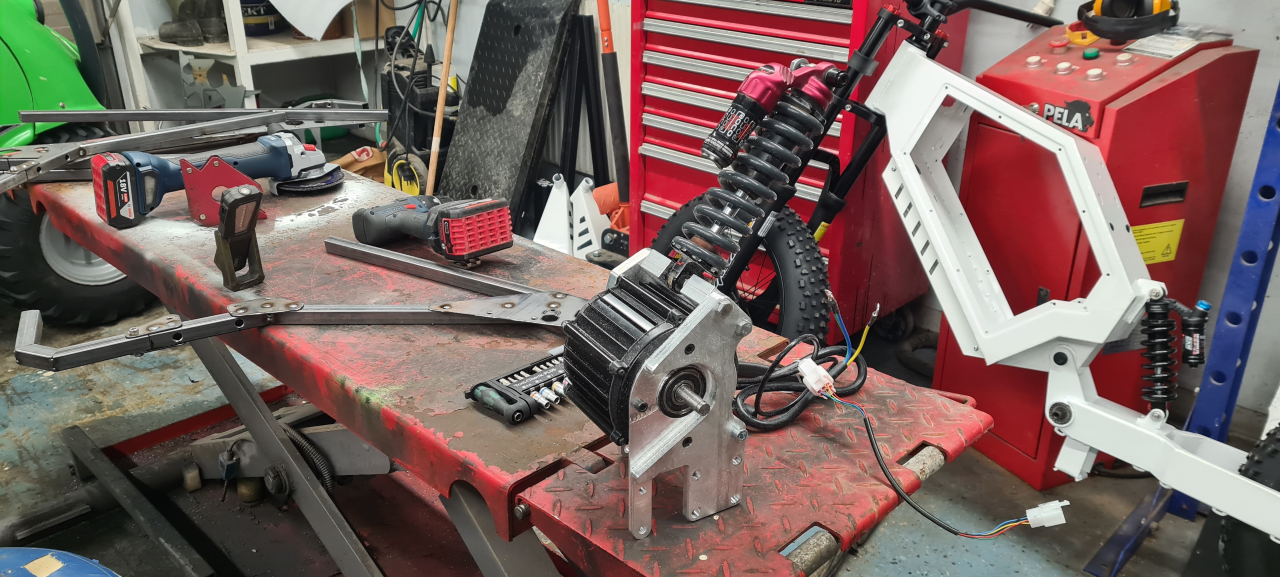

Unfortunately the 20×20 square tube mounted on the side of the frame interfere with the rear shock, the way I were planning on mounting it so I needed to come up with a new bracket.

So I cut a couple of ”ears” from 3mm steel sheet and welded the upper shock mount onto the frame. Now the stance of the bike is decided and it feels pretty OK.

The motor/shock mount is easily removed from the bike with just 9 M8 bolts. This is great for service and painting later on. If I may say so myself it looks frekkin’ awesome! 😀

Making the subframe

I decided to make the subframe from 20×20 square tubing as it’s strong enough, not too heavy, cheap and easy to get.

When this was done I just had to quickly weld everything together, drill and tap the mounting holes on the frame and make the joining parts for the subfrtame. The subframe goes under the bottom of the frame to be able to fit the footpegs.

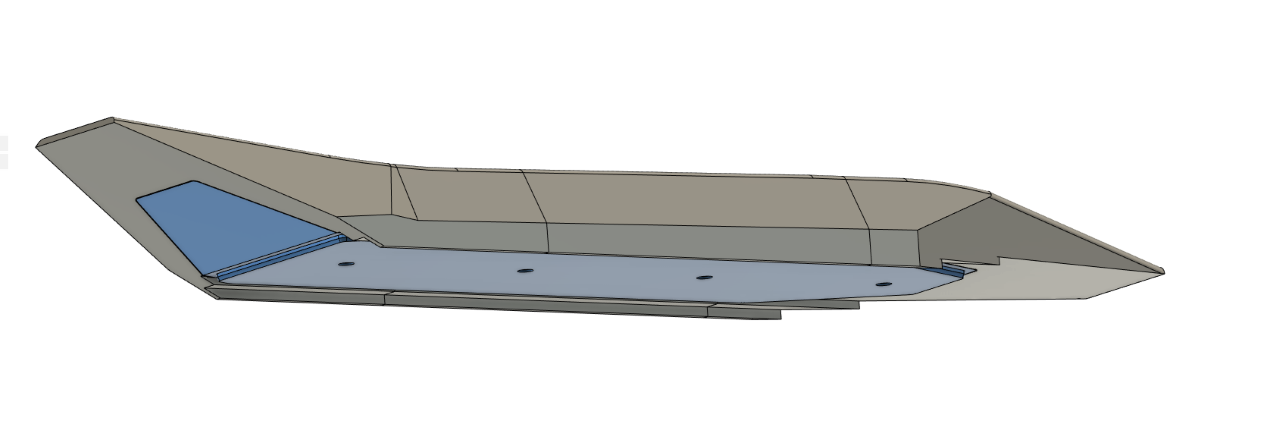

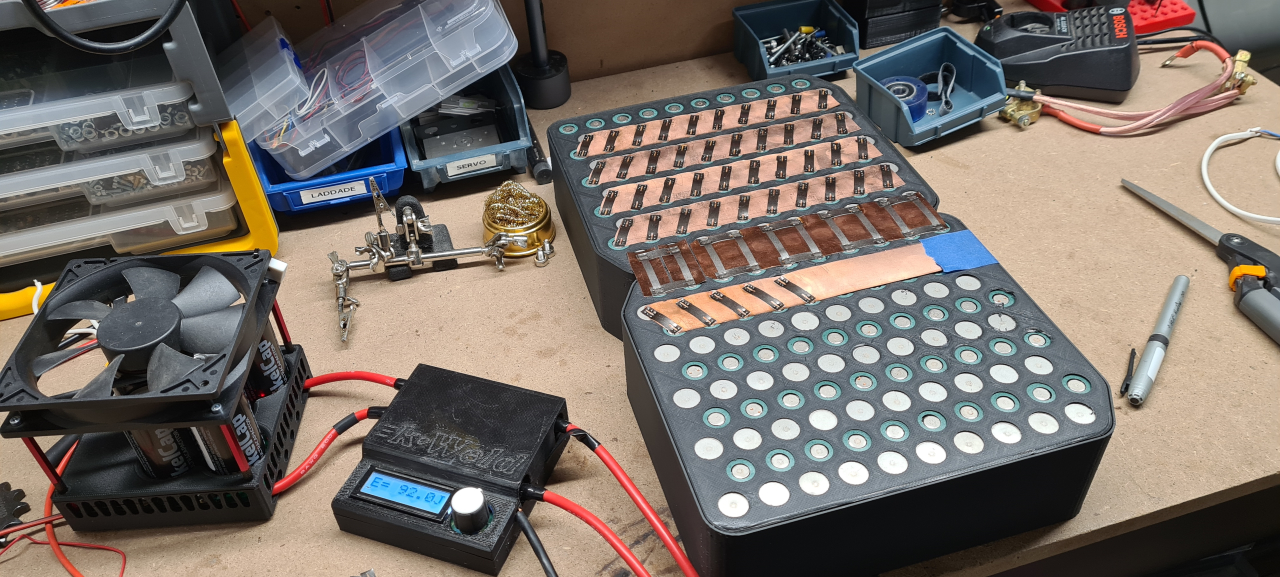

Battery and seat

So, that’s about where we are for now. What’s left is a few fairings, the seat, battery and electrics.. (And the brakes of course)

While the 3D-printer is making seat parts I’m finishing up the battery.

Well, that’s all for now. To be continued.