Ok, so the snow has started pouring down outside and I really feel the need for the Evant to run.. so this week I’ve been tinkering with the battery..

Since the motor/controller has a peak consumption of 200+ amps and the cells I’m building the battery from are able to push 35A continously giving a whooping 350A for the pack – I need something better than nickel strips to carry the current in this pack.. so I got the tip from a guy on a discord server to use copper sheets..

Copper conducts current 10-15 times better than the nickel strips I’ve been using, probably more since they’re more often than not just nickel plated steel strips.

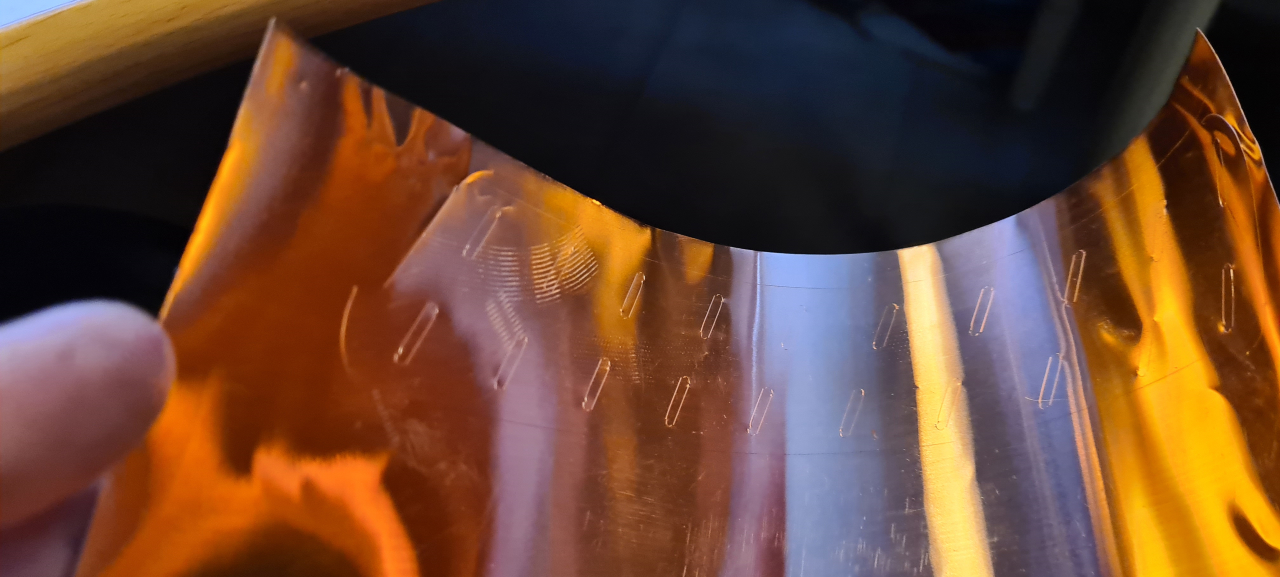

The thing with copper though is that it’s virtually impossible to weld with hobbyist equipment. That’s where RioCole showed me a method to get the copper sheet welded to the LiIon-cells using nickel plated steel strips as a conduit.

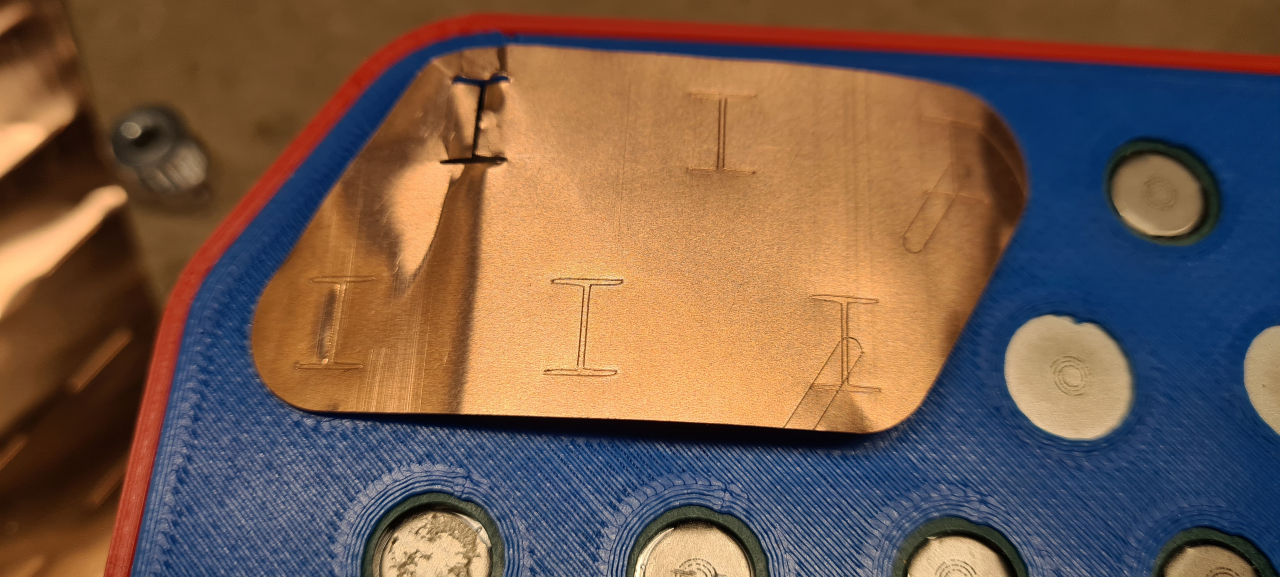

First of all I needed to cut the copper sheet to shape. It’s easy to do with a pair of scissors but I wanted better looks for my connecting copper. The design I make for the cell holders also make the poles of the cells sit recessed about 0.2mm, which requires that the copper sheet is able to bend down to weld properly.. to do that without distorting the entire sheet I need tabs that bend down which are hard to make manually..

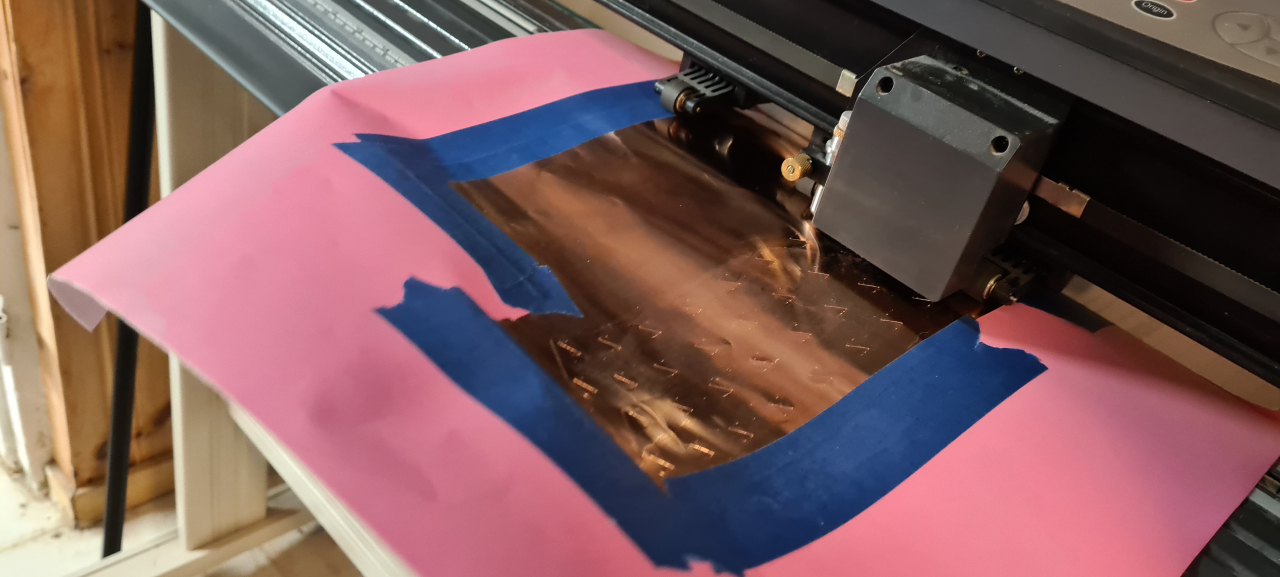

Then I realized that my vinyl cutter should be able to at least scratch the cu sheet.. At first I had trouble with the cutter not gripping the copper sheet properly which made it twist, but after taping it down to a piece of vinyl it works flawlessly!

I started out with some test pieces..

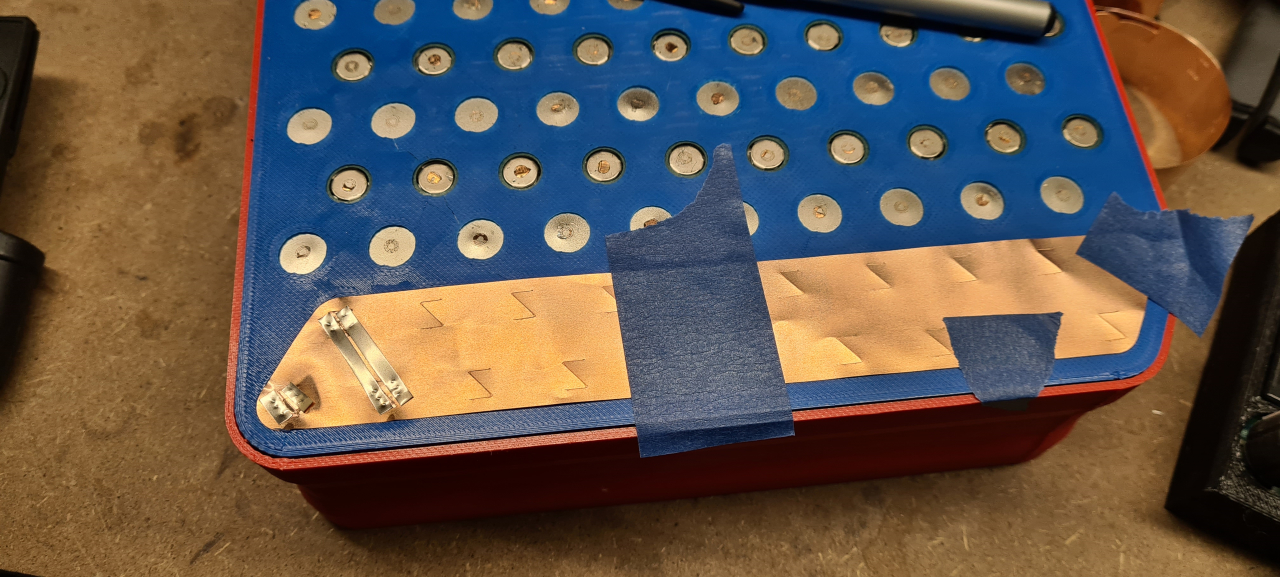

.. and then went for a design with a cut Z-slot..

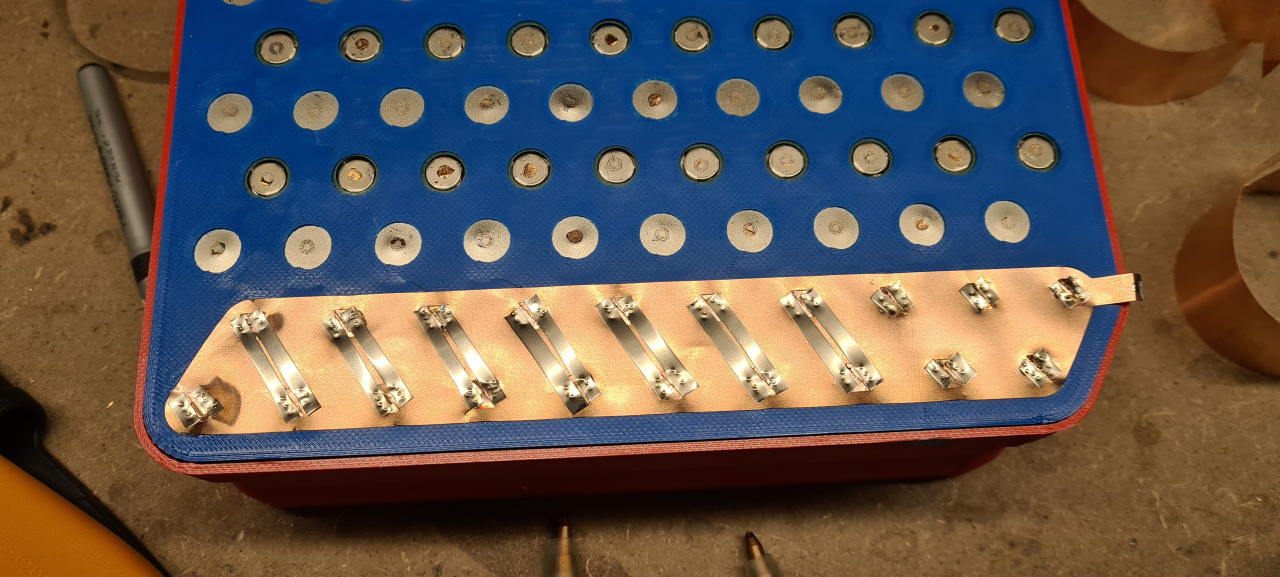

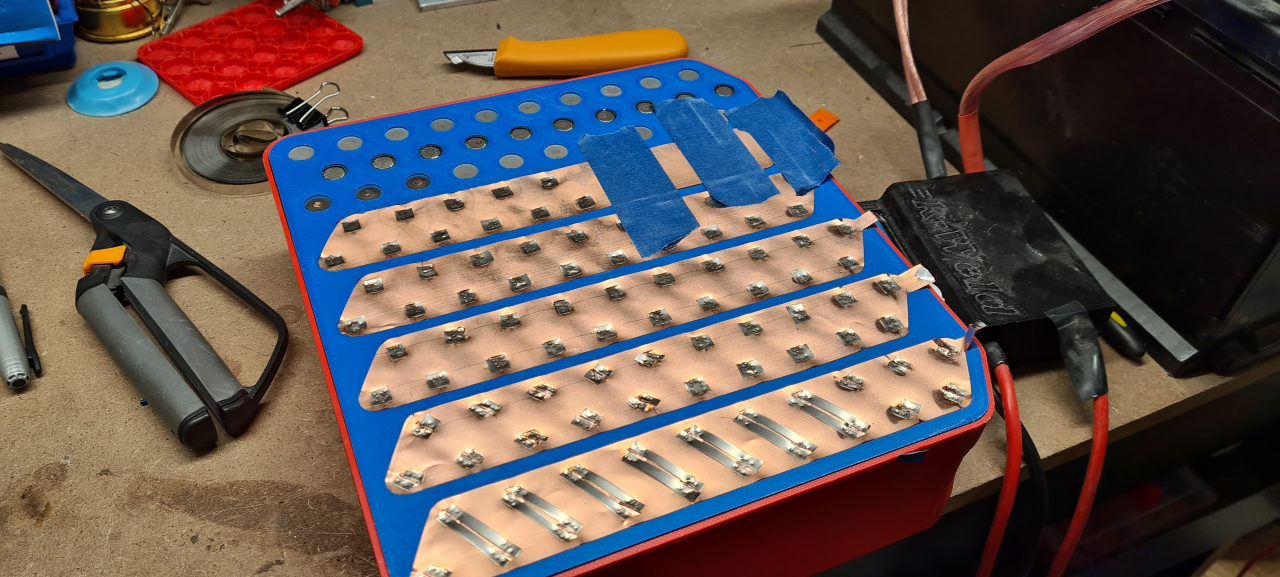

At first I thought that putting nickel strips in series would give me better current capabilities, but it was so much easier to get good welds with short pieces of nickel – so that’s what I did..

Starting to get the hang of welding the copper sheets to the cells. All connections are good and tested. The problem now is that the ANT BMS I got for this pack was too big to fit the casing I printed earlier.. so I had to redesign the battery box..

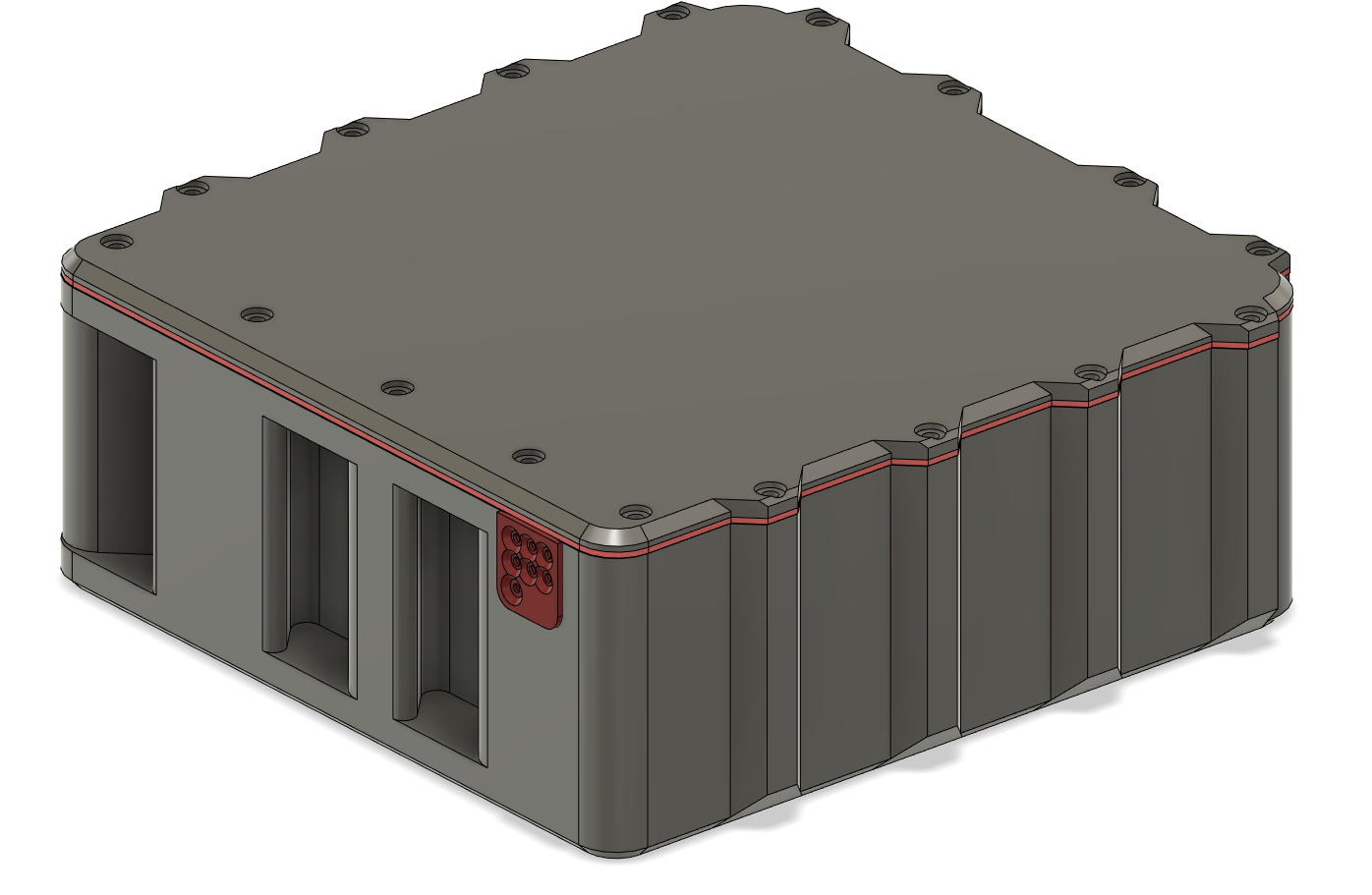

This beast is currently on the printer so an update will follow when it’s done printing and the battery is fully welded and ready for finishing..

TBC