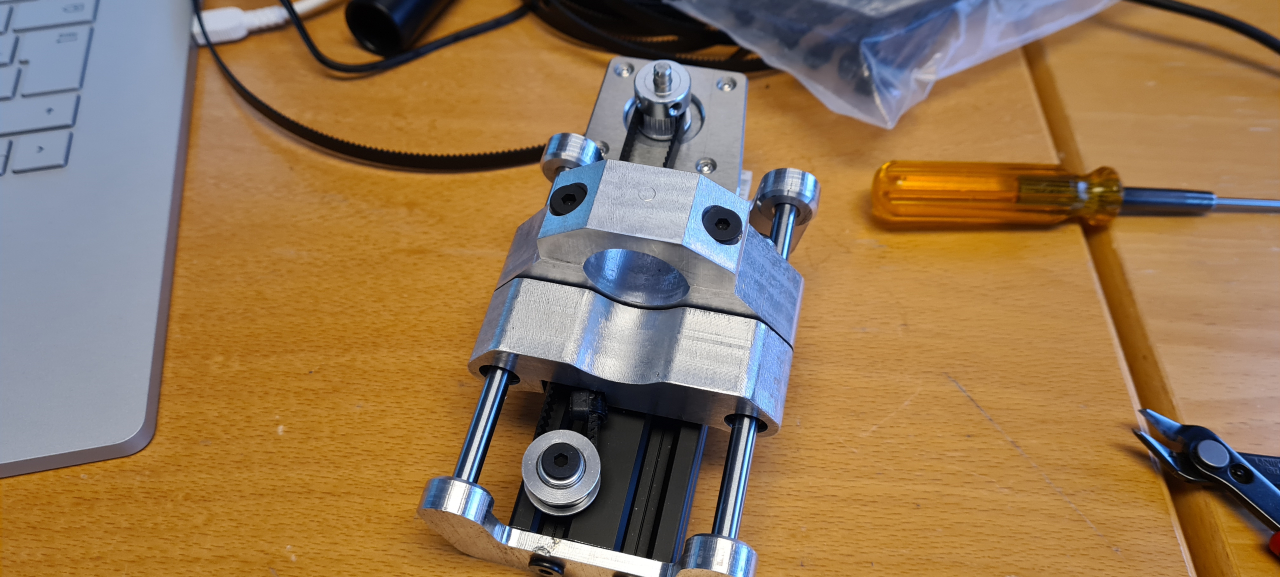

Well, since the mechanics were done a while ago what’s left is really just waiting for the new controller board to arrive to start making the electronics for the cutter. I’ve still made some changes to the Z-axis though to make it easier to adjust the belt tension..

These are the bolts that hold the belt on the Z..

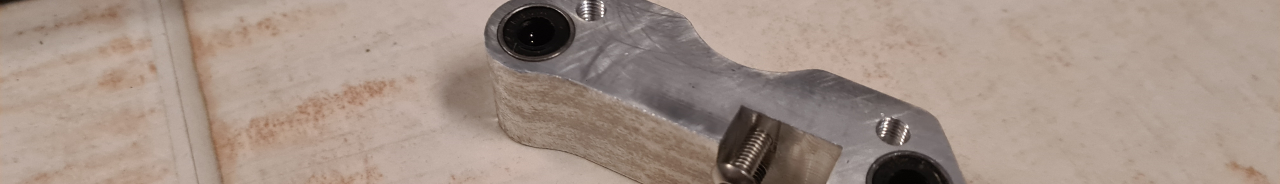

This was the intended idler holder where the belt tension was to be adjusted.. But as you can see, and what I didn’t think of, is that the idler obstructs the lower screw making adjusting belt tension hard using this..

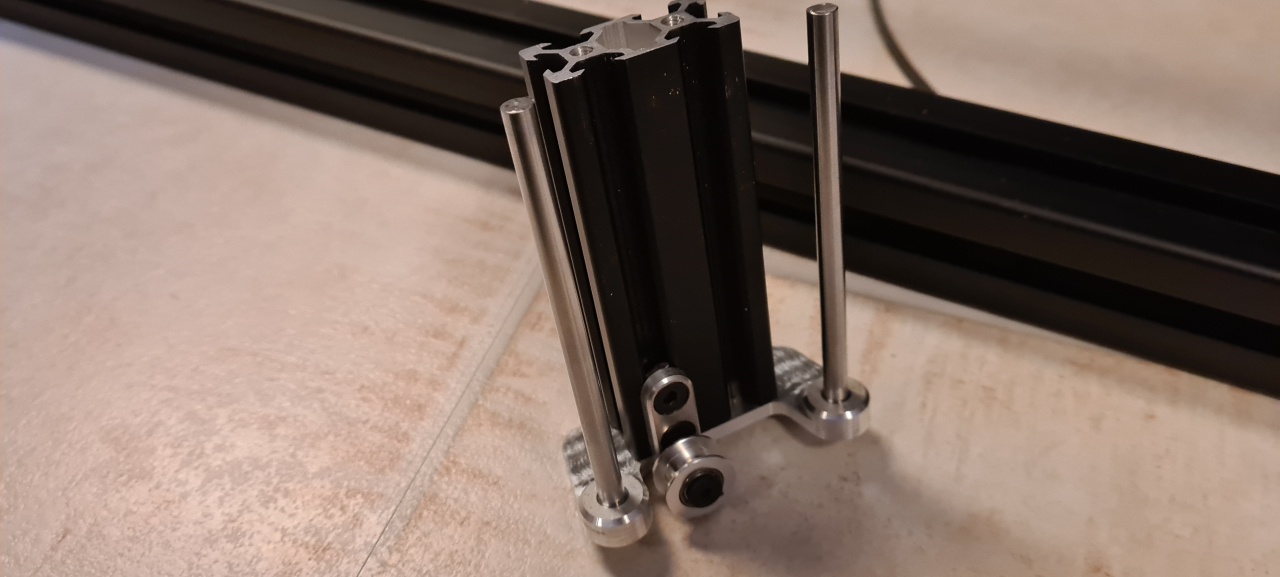

So instead I skipped the CNC:ed part and just attached the idler directly to a nut in the extrusion..

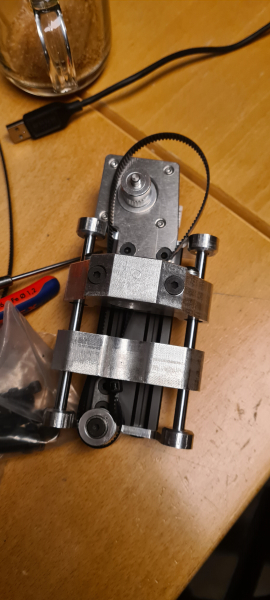

After attaching and tensioning the belt all three axis are driven by the belts and stepper motors.. So, if I only had some stepper drivers we could make the cutter move..

TBC