Back again and tonight has been a good night for the plasma..

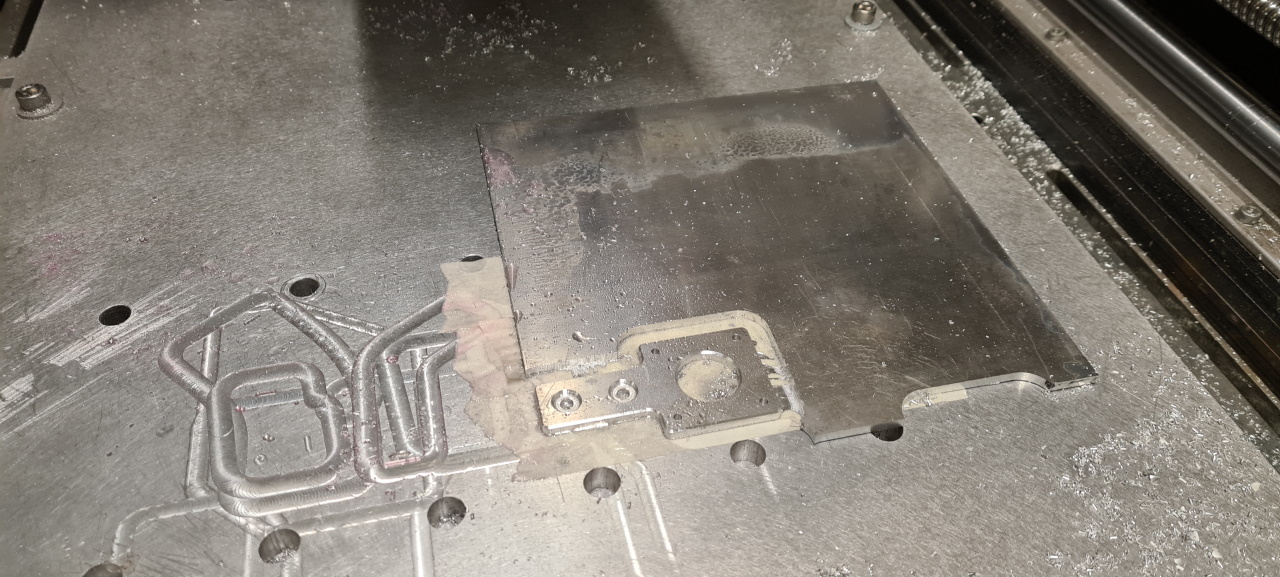

After a bunch of hours by the mill this is finally the last part that needs to be spat out before our building can commence.

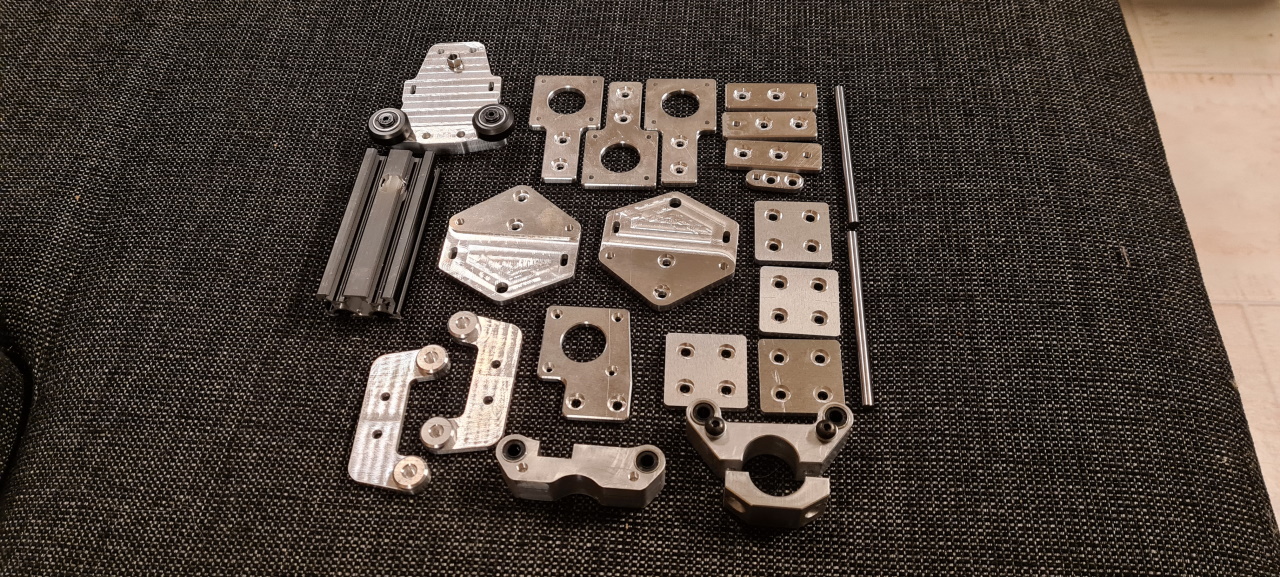

This small collection of parts seems to be all that’s needed in order to make the XYZ gantry for the CNC plasma cutter.. And when they’re all cut out I just could not resist the urge to do some assembly..

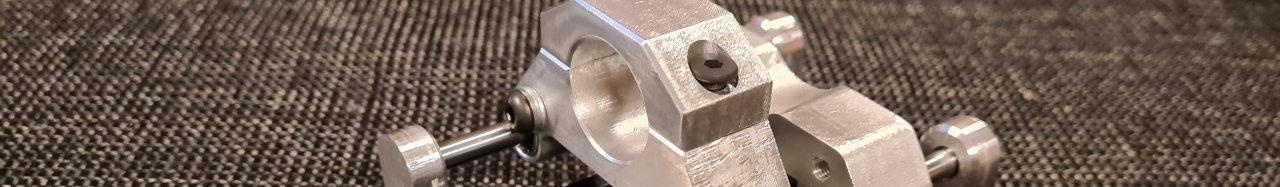

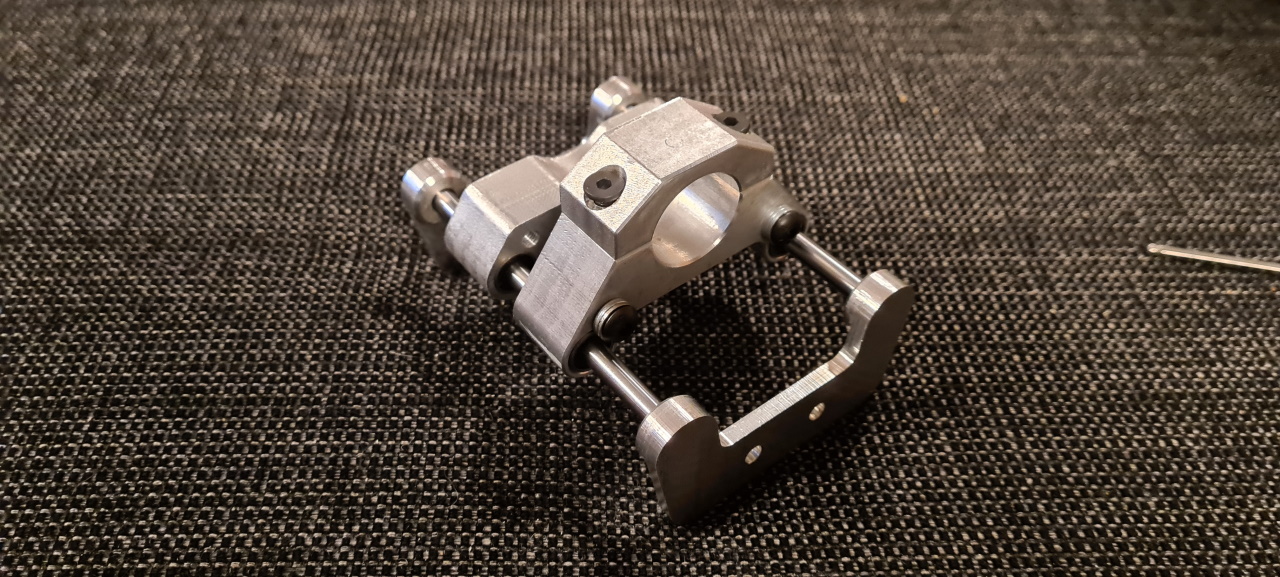

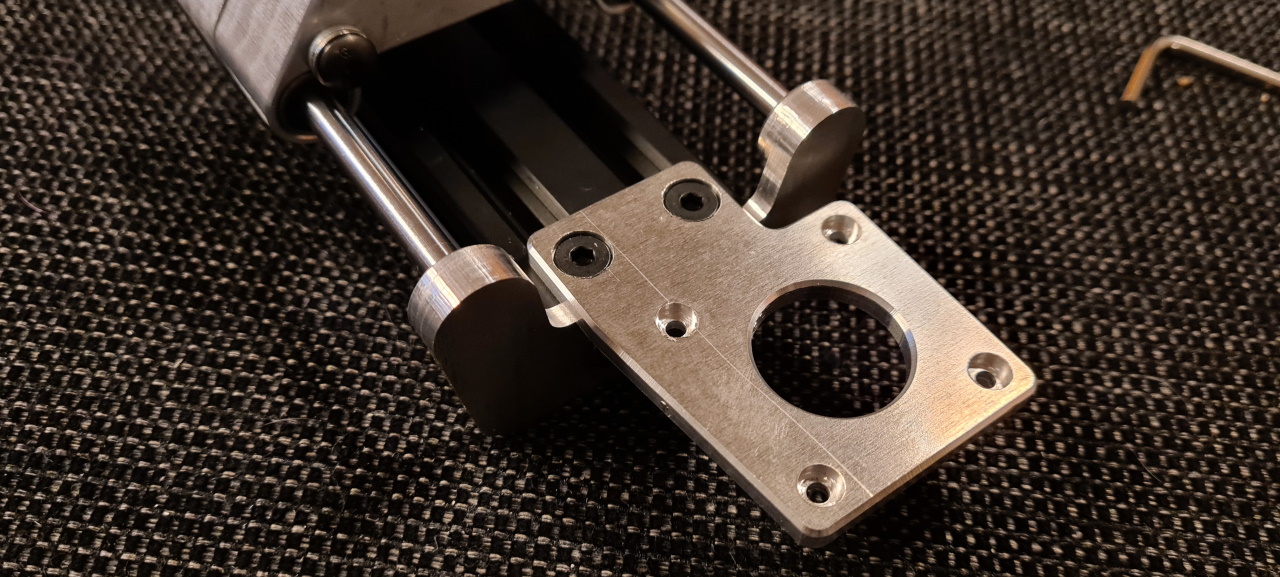

First of all the torch holder goes together with two screws. I’ve cheated and already mounted the linear bearings and the screws to hold them in place.

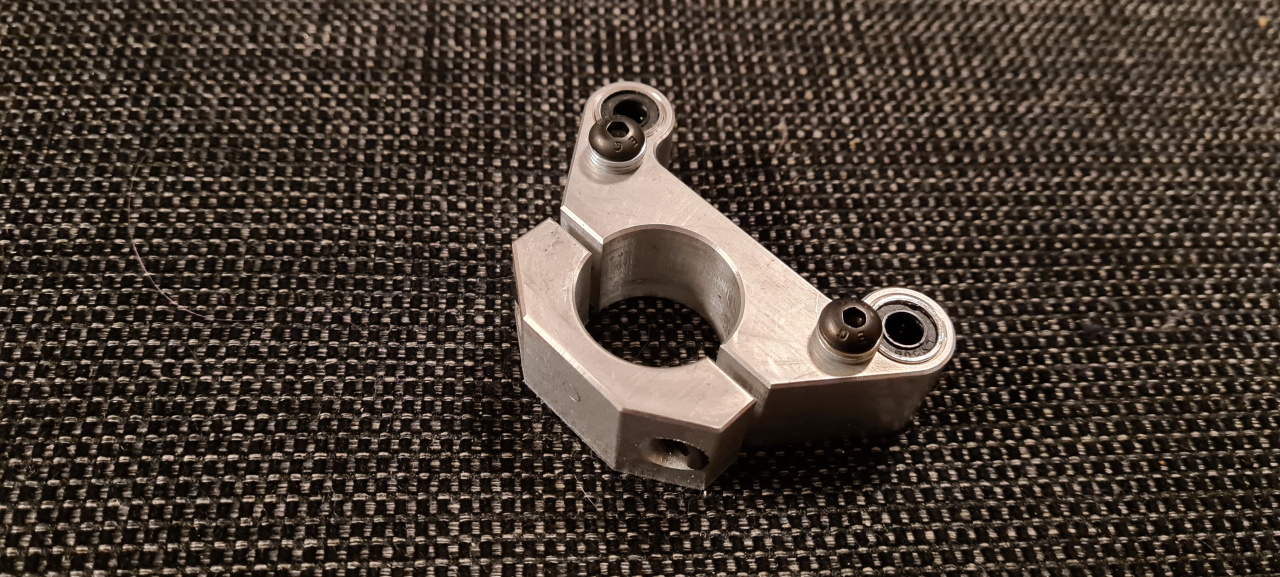

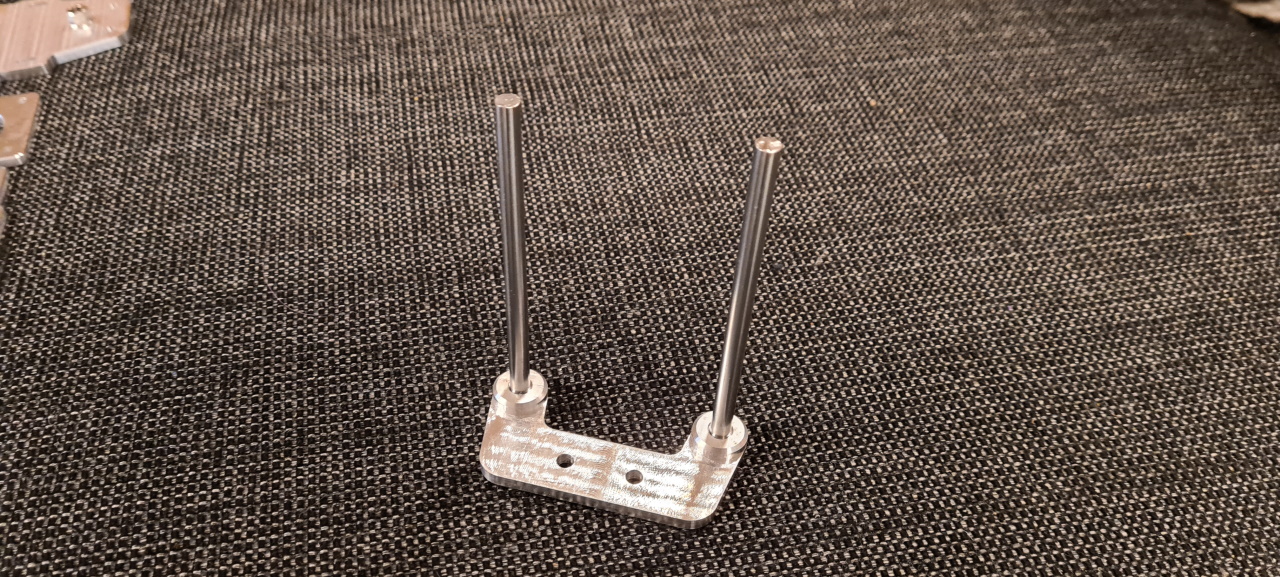

Then the Z-axis goes together by inserting the 104mm steel rods into the bottom bracket..

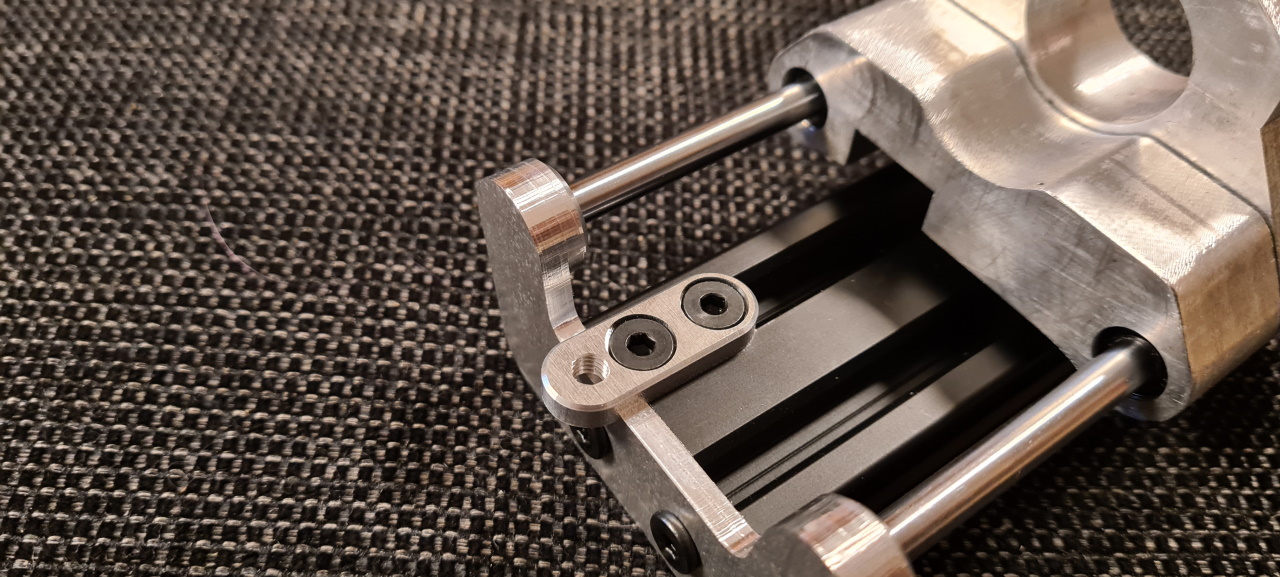

.. then the torch holder and lifter is slided onto the steel bars and finally the top bracket is mounted.

A 100mm long 2040 aluminium profile with threaded ends holds the assembly together. I’ll need to go back and add the contraption that is to hold the belt on the lifter but we’ll let that be for now.

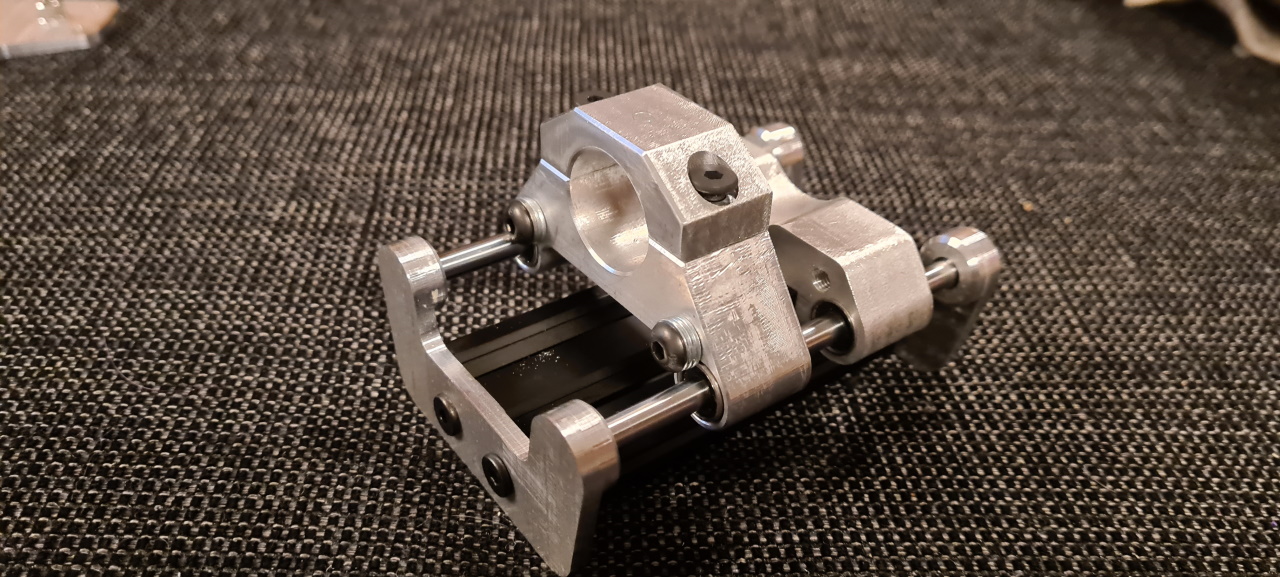

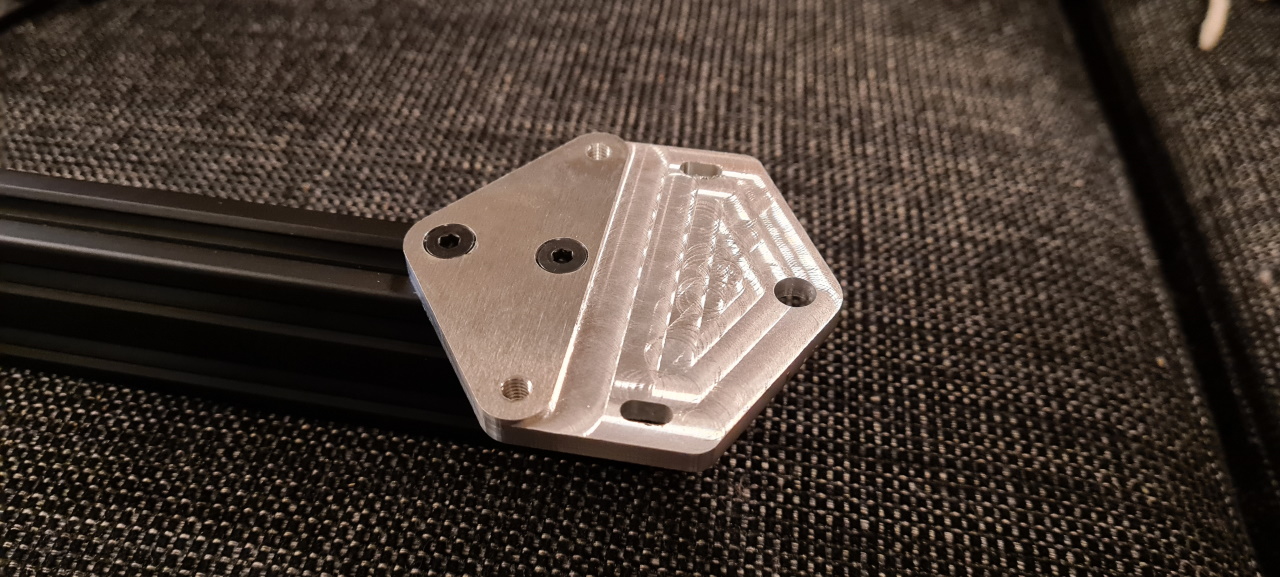

The idler pulley holder is added to the assembly..

.. and the Z stepper mount is attached.

After adding the backplate with the V-slot wheels the Z assembly is complete. This is the most complex part of the build, the rest is quite straightforward..

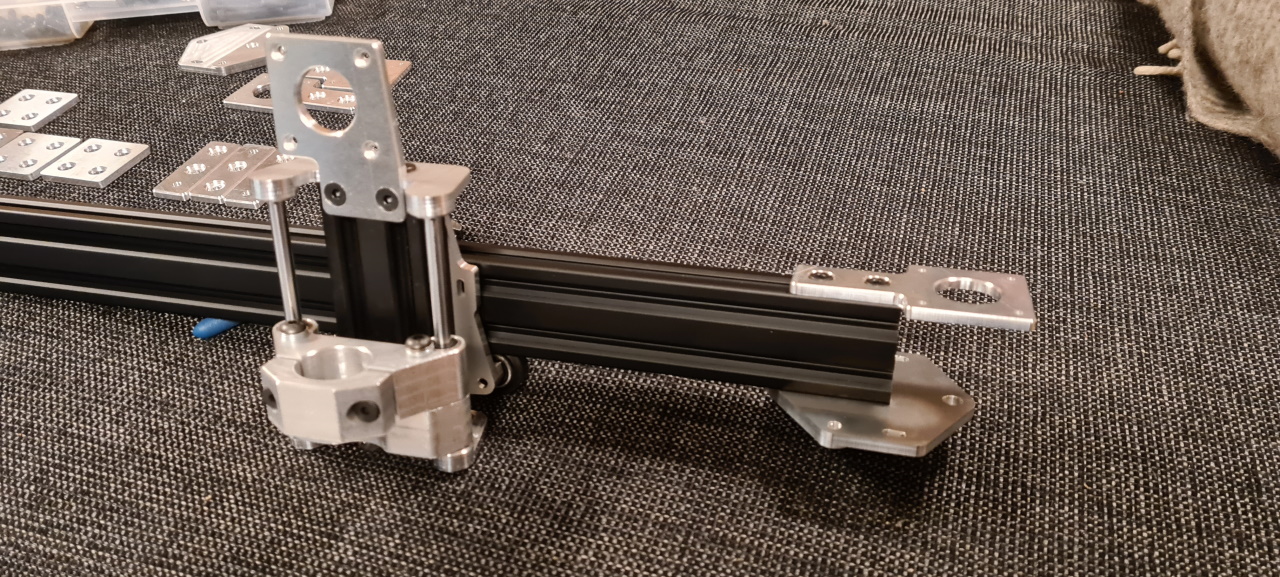

V-slot wheel brackets are added to the ends of the X axis profile. I’m using 1000mm long profiles so the cutter will span 1mx1m and have slightly less work area than that.

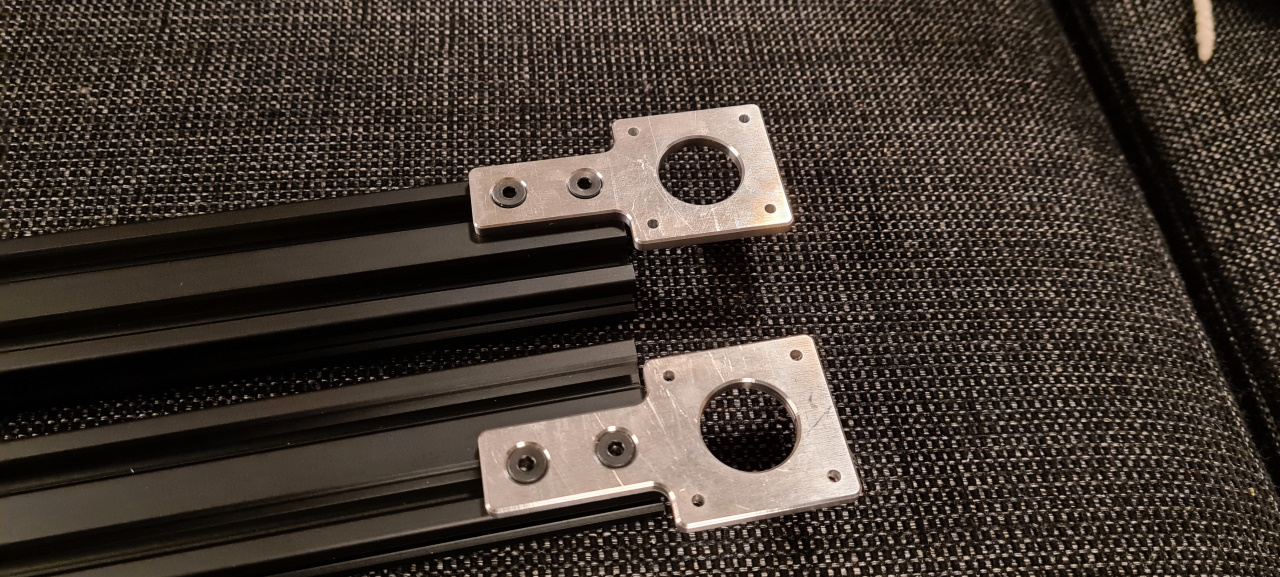

The mounting bracket for the X stepper motor is mounted..

The mounting bracket for the X stepper motor is mounted..

.. and the Z assembly is slided on to the X axis. Since the upper v-slot wheel is adjustable with an excentric nut the Z-axis can come off and be remounted any time but for now it was easier to just roll it on there before mounting the X idler holder..

.. which is the last part we need to complete the X axis. I’m not going to use limit switches for homing, I’ll probably just manually zero the X and Y axis where I want the work area to be like I do on the mill..

.. which is the last part we need to complete the X axis. I’m not going to use limit switches for homing, I’ll probably just manually zero the X and Y axis where I want the work area to be like I do on the mill..

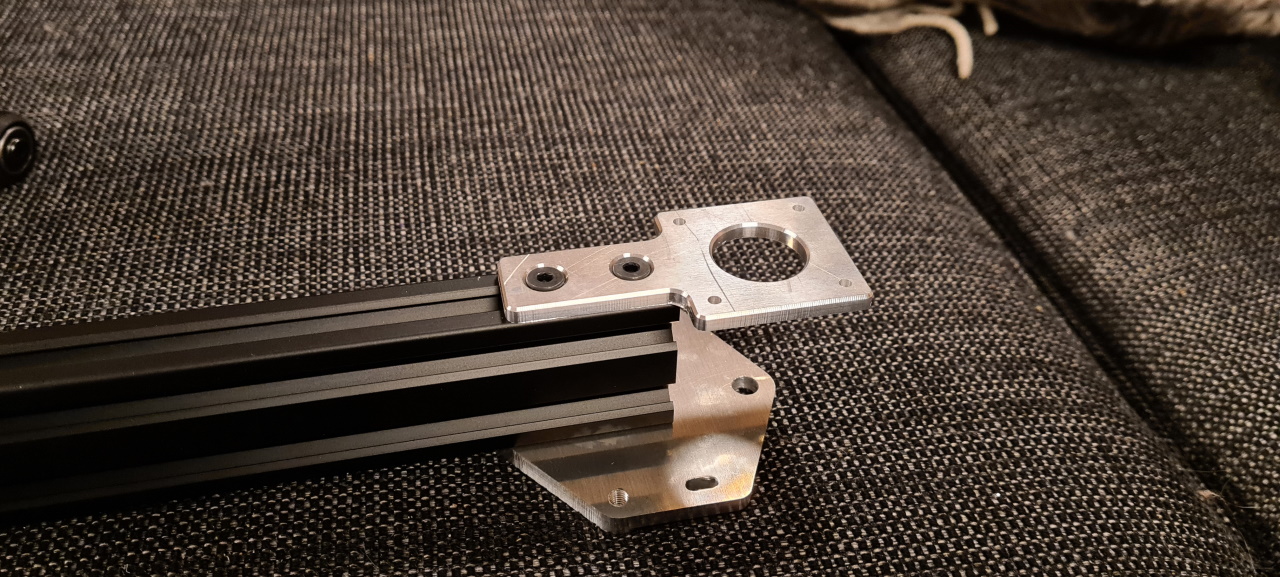

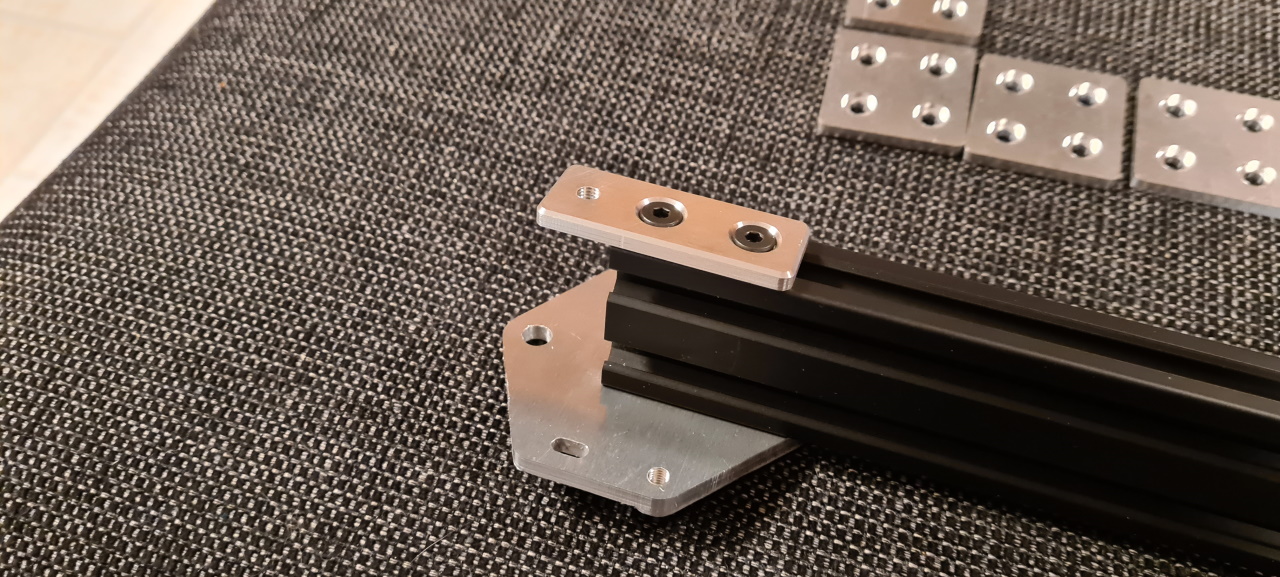

The Y axis stepper motor mounts are attached to 1000mm long 2040 extrusions..

The Y axis stepper motor mounts are attached to 1000mm long 2040 extrusions..

.. and the opposing idler mounts are attached…

.. and the opposing idler mounts are attached…

.. and this is the current state. I’ve mounted the Y axis brace holders in the corners of the motion rig but have yet to thread the ends of two more 1000mm extrusions.. Unfortunately I only have one at home so I’ll have to figure something out.. I was pretty sure I had 5pcs at home but it seems I was wrong.

.. and this is the current state. I’ve mounted the Y axis brace holders in the corners of the motion rig but have yet to thread the ends of two more 1000mm extrusions.. Unfortunately I only have one at home so I’ll have to figure something out.. I was pretty sure I had 5pcs at home but it seems I was wrong.

Well, almost all the mechanical parts are together now, tomorrow I’ll start with the electrical stuff to get the cutter to move on its own..

To be continued..