So, I’ve been repairing quite a lot of ebike batteries and to be able to re-use the old cells I need to get rid of all the nickel strips and spot welds that are on the cell poles. So for I’ve been using a side cutter to cut everything off to my best ability and then a dremel tool to grind off the remainder. The problem with this is that it’s quite messy and there’s a big risk of damaging the cells if grinding to much.

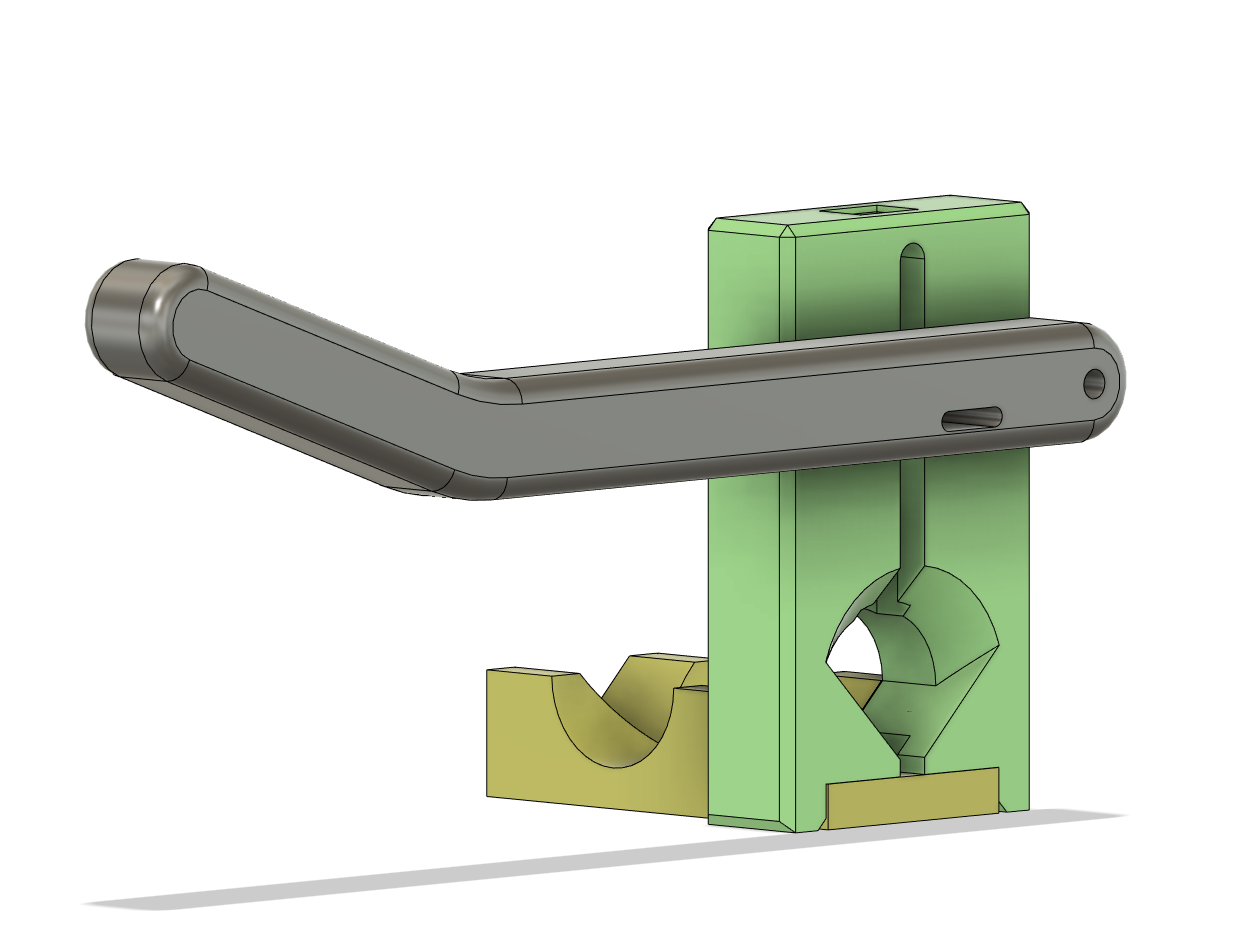

After wathing a youtuber make a servo-driven tool to cut the welds off 18650 cells I thought I’d give it a go, so I made a quick design in CAD.

It’s kind of a gilloutine with a cradle to support the battery cell and a grinded cutter (stump from a MGN-12 rail) that slides in a track.. I’d thought I’d see if a 3D-printed tool would suffice.

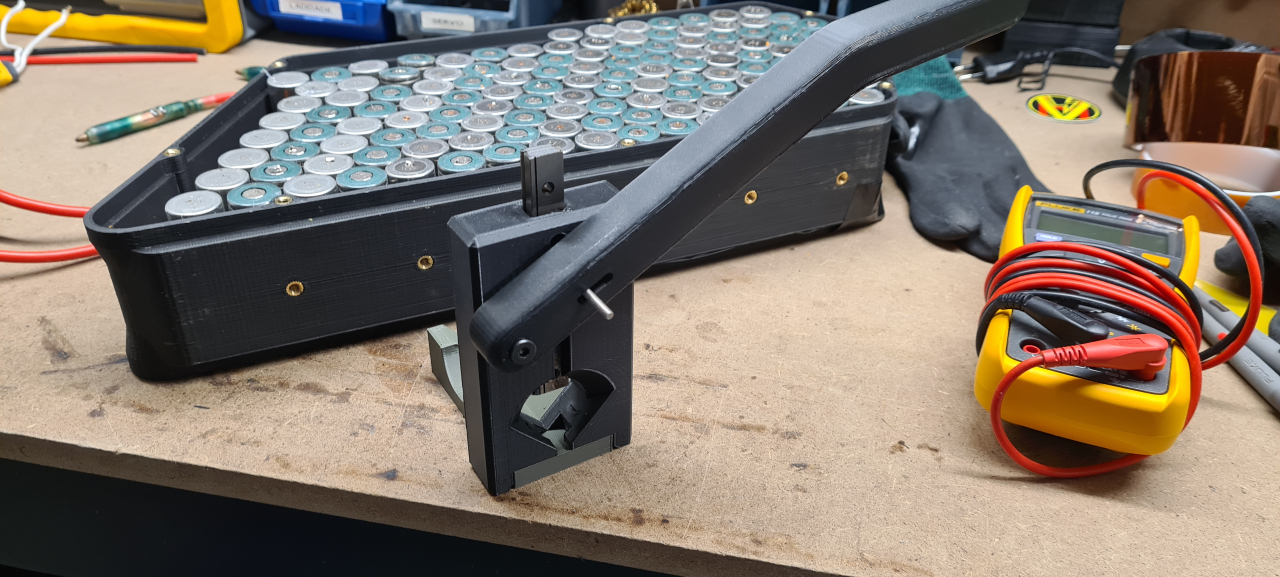

So, that’s what it looks like.

You slide the battery in as far as it goes, apply some pressure to keep it from sliding back and depress the handle.

And it cuts all the crap from the cell cap. It works fairly OK, I might need to re-grind the cutter to be more aggressive though.. but as for now I’m happy with the result. It’s on par with the grinding wheel without all the metal dust flying everywhere. Some welds and nickel strips take quite a lot of force to cut off though so we’ll see how long this tool’ll last.